TOP MATERIALS SERVICE

고객의 발전이 곧 대성티엠에스의 발전입니다

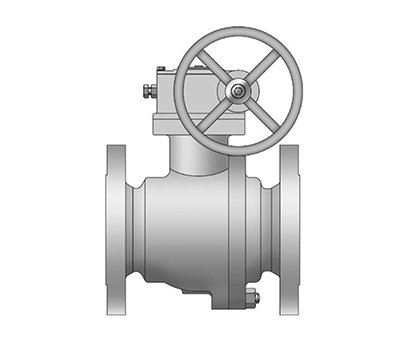

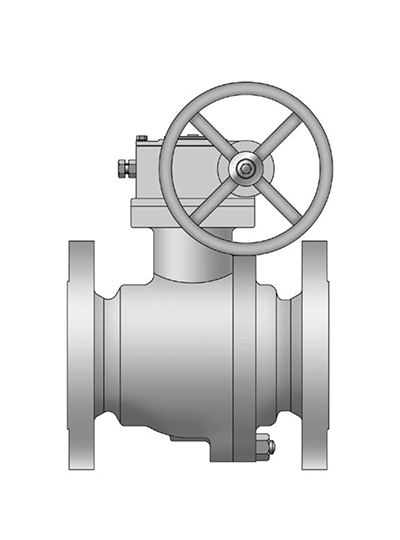

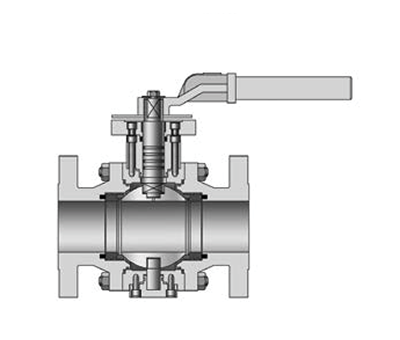

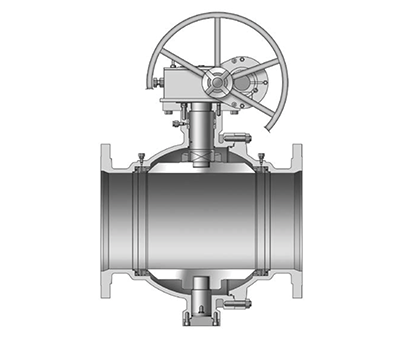

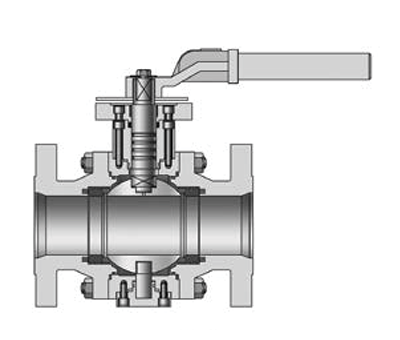

BALL VALVE

BALL VALVE

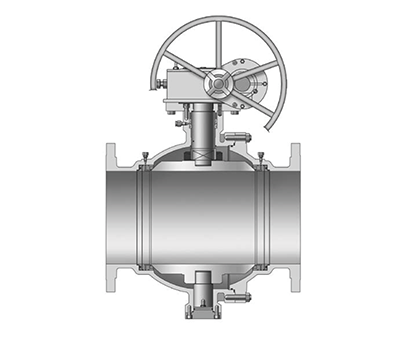

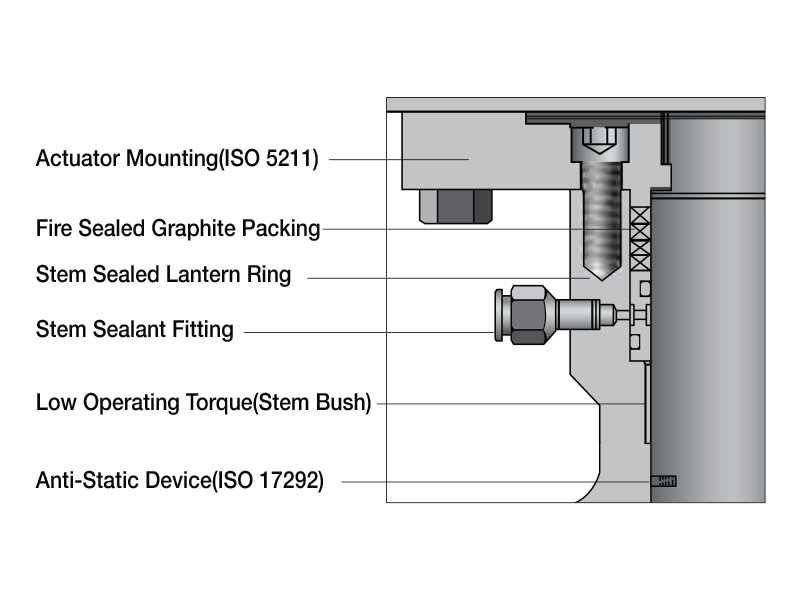

AT ALL TIMES-STEM SEAL

This option provides premier valve stem sealing characteristics for adverse conditions of extreme pressure/ temperture variations. Designed to meet the most stringent fugitive emission regulations,design is comprised of an extra deep stuffing box/packing/stem seal retainer & conical disc spring. The disc spring provide contiuous compression of the packing assembly and compensate for wear.

ACTUATOR MOUNTING ISO 5211

All top flanged end products shall have an integrally cast(ISO)actuator mounting pad. This feature provides for direct mount of gear operators or electric actuators. The additional cast for separate mounting bracket is eliminated.

STATIC SEALED STEM SEAL RETAINER

The stem seal retainer, with its(2) static viton o-ring seals; Accepts the forces provided by the combination iso mounting pad/packing gland & transmits those forces as packing/disc spring factory pre-load. A variety of o-ring seals are available for those exceptionally demanding applications. Field maintenance & costly repairs are virtually eliminated.

SPRING FORCE

Optional conical disc springs insure adequate loading of packing at all times. Excessive stem torque and packing deformation due to over-tightening of conventional packing glands is eliminated. The constant "LOAD" provided by the disc springs compensates for normal wear-repair and maintenance costs are virtually eliminated.

PACKING

The high pressure/high temperature packing set is comprised of self-cleaning, die-formed, high-density and low-density graphite molded packing materials. This unique design eliminates stem galling, lowers required valve stem torque and increases product performance.

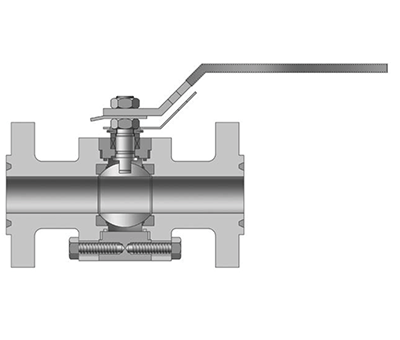

ANTI-STATIC DESIGN ISO17292

Ball valve present a particular problem with the build up of static electricity auound the ball. They have anti-static design which provides contact between stem and ball, and stem and body to eliminate static electricity.

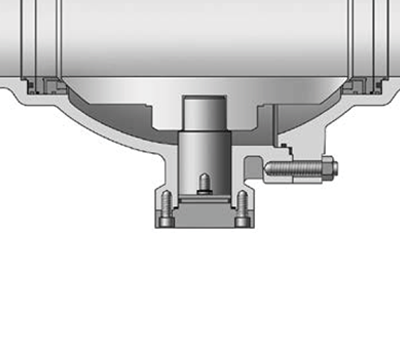

TRUNNION LOW STEM DESIGN

-

Trunnion mount design locates the low stem trunnion assembly within the confines of body & cap. In so doing, both the line pressure and media act upon all valve cavity components equally.

The advantages of such a design include:

1. The pressure & media does not concentrate in one location only, instead the forces are dispersed equally throughout the pressurized areas.

2. Ball movement and side loading of lower stem is minimized, thereby decreasing operational torque valve and improving stem seal life end.

3. Gurantee the low torque and extend valve life. -

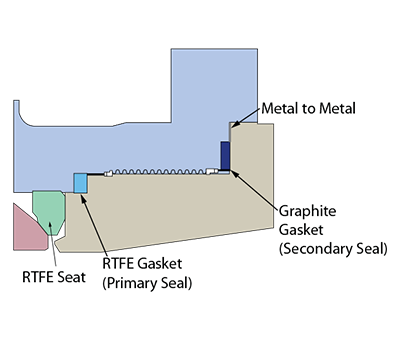

UNIQUE DOUBLE SEALING DESIGN AND METAL TO METAL CONTACT

-

The PTFE gasket acts as the primary seal for top unibody ball valve. the secondary seal is made of flexible graphite; A material with extremely good resistance to fire conditions.

-

APPLICATION OF SEAT PER TEMPERATURE

좌우로 스크롤해서 확인하세요.

| CLASS | SEAT METARIAL | DESIGN TEMPERATURE |

|---|---|---|

| 150# | RTFE | - 50℃ ~ +180℃ |

| 300# | RTFE | - 50℃ ~ +150℃ |

| 600# | RTFE | - 50℃ ~ +100℃ |

| 900# | NYLON(DEVLON) | - 45℃ ~ +190℃ |

| 1500# | NYLON(DEVLON) | - 45℃ ~ +170℃ |

| 2500# | NYLON(DEVLON) | - 45℃ ~ +160℃ |

| ALL CLASS | PEEK | 200℃ & OVER |

| ALL CLASS | METAL | 250℃ & OVER |