TOP MATERIALS SERVICE

고객의 발전이 곧 대성티엠에스의 발전입니다

BELLOWS SEAL VALVE

BELLOWS SEAL VALVE

OPERATIONAL SERVICE FEATURES

In a maintenance aspect, it is true that this type of valve is accounted less than any other type, but the valve have some important advantages as follows:

1.Useful life is ensured.

2.There is a grease nipple on all bellows seal gate valve under current production to ensure correct lubrication over yoke bush.

The threads on stem in every kind of bellows seal valve should be kept clean if possible and lubricated periodically with high temperature grease.

It is recommended the preventive maintenance should be carried out at least every three months.

The maintenance has a particular importance when the valve is employed to high temperature application in case it is essential to use a grease of high temperature type.

At this time, it is desirable that the valve is operated from open to shut, and vice versa.

-

-

VALVE SELECTION

As a general guide to valve selection suitable for a specific application, the gate valve should be used mainly for low or medium pressure steam, steam tracing lines, or other services such as heat transfer.

The globe valve should be selected for medium or high pressure steam, where the isolation of vessels may be involved in safety problem. It is also used for toxic or explosive media handling and in every case that a trouble may occur in flow regulation.

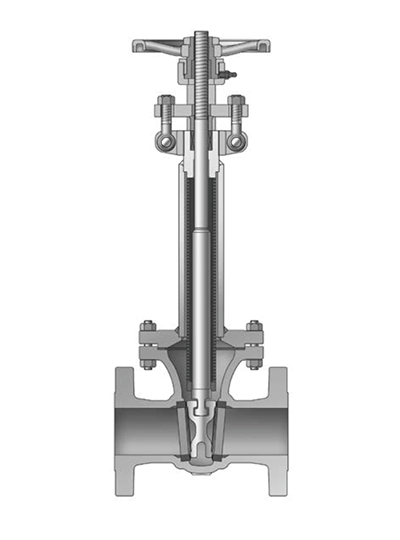

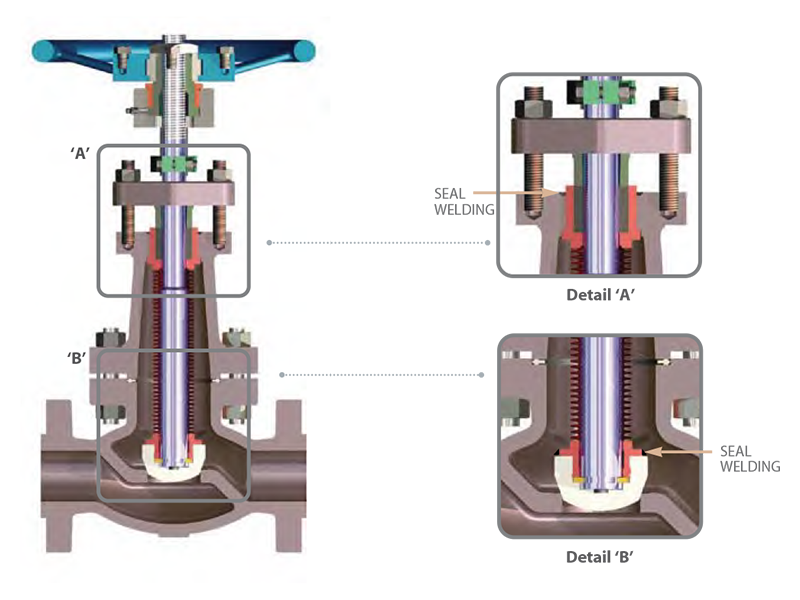

It should be noted that we have a specially designed valve of which dry escape to gas or fluid is completely prevented. In the valve, conventional stem packing is replaced with flexible metallic membrane where all possible leaking paths through stem or body/bonnet joint are welded.

The bellows units applied to this valve were tested for life cycle to destruction, resulting in satisfactory test results meeting the life time, temperature, and pressure requirements of ASME B16.34.

LOW FUGITIVE EMISSION VALVE

Low Fugitive emission Valve (LFV) is designed and manufactured to ensure leakage of less than 100 ppm of volatile organic compounds. PK Valve has established the test facilities and made its own procedures with Emission Defence Packing (EDP) for fugitive emission test. By using the test facilities and procedures, room temperature cycle and thermal cycle testing have been performed, establishing critical design parameters necessary to achieve low fugitive emissions.

PRODUCTION MATERIALS

- Bellows Set : 321SS(Bellows) + 316SS(Holder)

- Carbon Steel : ASTM A216-WCB or Equivalent

- Stainless Steel : ASTM A351-CF8, CF8M, CF3, CF3M or Equivalent

- ASME SA designation material(e.g. ASME SA351-CF8M)

좌우로 스크롤해서 확인하세요.

| class/type | 150 | 300 | 600 |

|---|---|---|---|

| GATE | 2-24 | 2-24 | 2-24 |

| GLOBE | 1/2-24 | 1/2-24 | 2-24 |

GATE VALVE / GLOBE VALVE

-

GATE VALVE

-

GLOBE VALVE

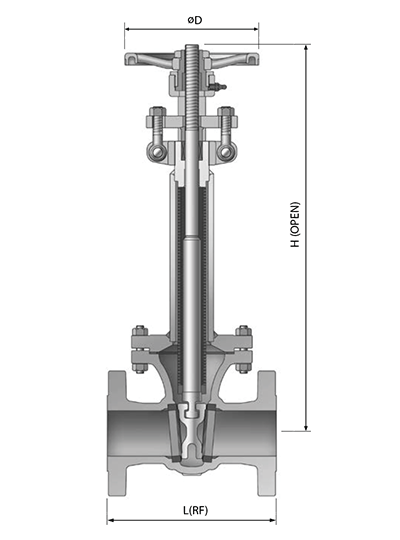

GATE VALVE

APPLICABLE STANDARD SPECIFICATION

- BELLOWS INSPECTION AND TEST : MSS-SP-117

- END FLANGE : ASME B16.10

- BUTT WELDING ENDS : ASME B16.25

- SHELL WALL THICKNESS : ASME B16.34 OR API 600

- FACE TO FACE : ASME B 16.10

DIMENSION AND WEIGHT

좌우로 스크롤해서 확인하세요.

CLASS 150

UNIT : mm

| SIZE | 2 | 3 | 4 | 5 | 6 | 8 |

|---|---|---|---|---|---|---|

| L | 177.8 | 203.2 | 228.6 | 254.0 | 266.7 | 292.1 |

| D | 200 | 224 | 355 | 315 | 355 | 400 |

| H | 639 | 890 | 1272 | 1141 | 1209 | 1588 |

CLASS 300

UNIT : mm

| SIZE | 2 | 3 | 4 | 5 | 6 | 8 |

|---|---|---|---|---|---|---|

| L | 215.9 | 282.4 | 304.8 | 381.0 | 403.4 | 419.1 |

| D | 200 | 224 | 355 | 315 | 355 | 400 |

| H | 639 | 890 | 1272 | 1141 | 1209 | 1588 |

CLASS 600

UNIT : mm

| SIZE | 3 | 4 |

|---|---|---|

| L | 355.6 | 431.8 |

| D | 250 | 355 |

| H | 974 | 1272 |

STANDARD MATERIAL SPECIFICATIONS

좌우로 스크롤해서 확인하세요.

| NO. | PART NAME | MATERIAL |

|---|---|---|

| 1 | BODY | A216 - WCB |

| 2 | YOKE | A216 - WCB |

| 3 | WEDGE | A217 - CA15+STL |

| 4 | STEM | A479 - 410 |

| 5 | HAND WHEEL | A197 |

| 6 | BODY SEAT RING | A576 - 1020+STL(S20C) |

| 7 | BELLOWS | STAINLESS STEEL TYPE321+316 |

| 8 | GASKET | SPIRAL WOUND / GRAPHITE+304+304 |

| 9 | PACKING | GRAPHITE+GRAPHITE WITH INCONEL WIRE |

| 10 | GLAND FLANGE | A283 - D |

| 11 | HINGE BOLT | A307 - B |

| 12 | HINGE NUT | A194 - 2H |

| 13 | HINGE PIN | A576 - 1020 |

| 14 | PACKING GLAND | A576 - 1020+Cr |

| 15 | BONNET BOLT | A193 - B7 |

| 16 | BONNET NUT | A194 - 2H |

| 17 | YOKE CAP | A576 - 1020 |

| 18 | YOKE SLEEVE | A439 - D2C |

| 19 | HANDLE NUT | A47 - 32510+Zn |

| 20 | SET SCREW | STEEL |

| 21 | NIPPLE | STEEL+Cr |

| 22 | FLANGE | A216 - WCB |

| 23 | EXTENSION PIPE | A106 - B |

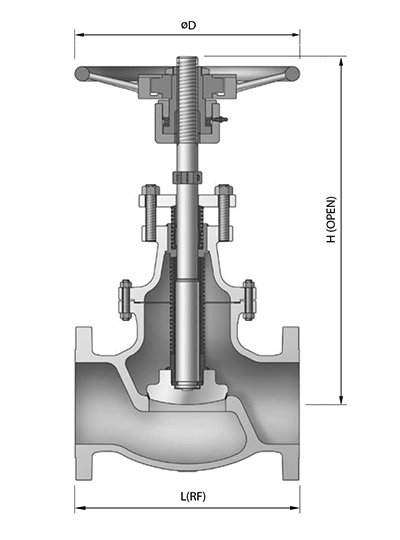

GLOBE VALVE

APPLICABLE STANDARD SPECIFICATION

- BELLOWS INSPECTION AND TEST : MSS-SP-117

- END FLANGE : ASME B16.10

- BUTT WELDING ENDS : ASME B16.25

- SHELL WALL THICKNESS : ASME B16.34 OR API 600

- FACE TO FACE : ASME B 16.10

DIMENSION AND WEIGHT

좌우로 스크롤해서 확인하세요.

CLASS 150

UNIT : mm

| SIZE | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 |

|---|---|---|---|---|---|---|---|---|

| L | 203.2 | 215.9 | 241.3 | 292.1 | 355.6 | 406.4 | 495.3 | 622.3 |

| D | 200 | 200 | 224 | 355 | 400 | 450 | 560 | 560 |

| H | 413 | 378 | 432 | 579 | 670 | 773 | 945 | 1208 |

CLASS 300

UNIT : mm

| SIZE | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 |

|---|---|---|---|---|---|---|---|---|

| L | 266.7 | 292.1 | 317.5 | 355.6 | 400.1 | 444.5 | 558.8 | 622.3 |

| D | 200 | 200 | 224 | 355 | 400 | 450 | 560 | 560 |

| H | 364 | 378 | 432 | 569 | 670 | 773 | 945 | 1213 |

CLASS 600

UNIT : mm

| SIZE | 2½ | 3 |

|---|---|---|

| L | 330.2 | 355.6 |

| D | 355 | 355 |

| H | 576 | 583 |

STANDARD MATERIAL SPECIFICATIONS

좌우로 스크롤해서 확인하세요.

| NO. | PART NAME | MATERIAL |

|---|---|---|

| 1 | BODY | A216 - WCB |

| 2 | BONNET | A216 - WCB |

| 3 | DISC | A216 - WCB+STL |

| 4 | STEM | A479 - 410 |

| 5 | HAND WHEEL | A216 - WCB |

| 6 | BODY SEAT | A216 - WCB+STL |

| 7 | BELLOWS SET | STAINLESS STEEL TYPE321+316 |

| 8 | GASKET | SPIRAL WOUND / GRAPHITE+304+304 |

| 9 | PACKING | GRAPHITE+GRAPHITE WITH INCONEL WIRE |

| 10 | GLAND FLANGE | A105 |

| 11 | HINGE BOLT | A307 - B |

| 12 | HINGE NUT | A194 - 2H |

| 13 | PACKING GLAND | A576 - 1020+Cr |

| 14 | BONNET BOLT | A193 - B7 |

| 15 | BONNET NUT | A194 - 2H |

| 16 | YOKE | A283 - D |

| 17 | YOKE SLEEVE | A439 - D2C |

| 18 | YOKE CAP | A576 - 1020 |

| 19 | STOPPER | A216 - WCB |

| 20 | BOLT | A307 - B |

| 21 | NUT | A563 - A |

| 22 | HAND WHEEL NUT | A47 - 32510+Zn |