TOP MATERIALS SERVICE

고객의 발전이 곧 대성티엠에스의 발전입니다

GASKET

GASKETS

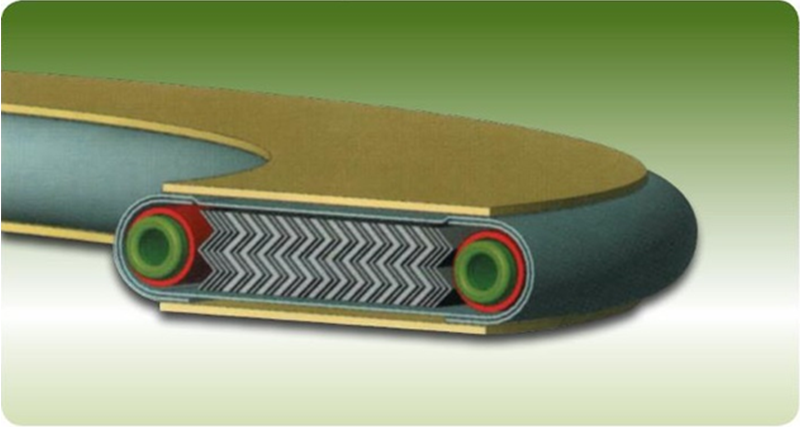

Hi-Flex Gasket

Hiflex Metal Gasket consists of GRAFLEX, metal O-Ring, Metal clad & Sprial Wound Gasket(or Corrugated Metal Gasket or Meral Tube), which are formed one body. As a result of this, it shows a broad sealing width, improvement of sealing capacity and sufficient elasticity in high load compared with spiral wound gasket in same size.

KUKIL INNTOT Hiflex Metal Gaskets are almost without any size limitations.

Not only standard size such as ASME/ANSI B16.5, ASME/ANSI B16.47 Series A&B, JIS & DIN but also the non-standard type sized over 3000mm O.D are available. lt is suitable for various kind of Flanges such as Raiased Face, Male-Female & Tongue and Groove etc. and can be formed to be Round, Oval & Square shapes and can have partition bars for Heat Exchangers & Pressure vessels.

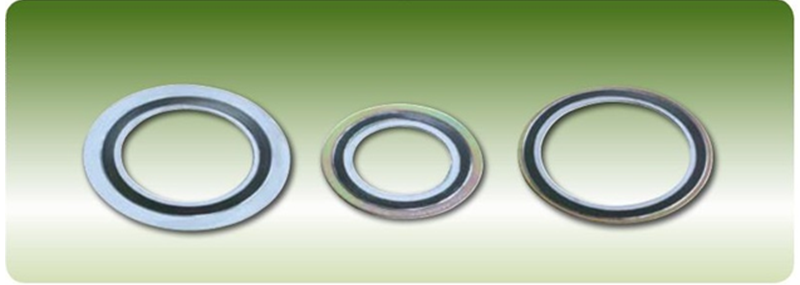

Spiral Wound Gasket

- INTRODCTION

Over the last decade high quality Spiral Wound Gaskets have proved themselves to be the most reliable sealing element for use in difficult, critical and arduous duties. This applies particularly in the Refinery, Petrochemical, Chemical, Steam Raising and Prdocess industries, where they have many advantages over the older types of gaskets. e.g - SEAL MAINTAINED UNDER THE MOST EXACTING CONDITIONS

From cryogenic to at least 538℃(1000℉) - Thermal cycling, Vibration, Mechanical shock, Dry gases, High vacuum. - EASE OF INSTALLATION

Quick and simple fo fit Do not need Grooved or Lapped flange face finishes. Can often be used on pitted or misaligned flanges where other gaskets have failed. Don't cause corrosion. Do not adhere to flange faces when opened thus reducing expensive cleaning time. - CONTROLLED COMPRESSIBILITY

By altering the tension, number and thickness of the windings in the gasket construction, an infinite number of stress values can be produced to suit the actual design and service conditions, thus ensuring a constant gasket stress at all times.

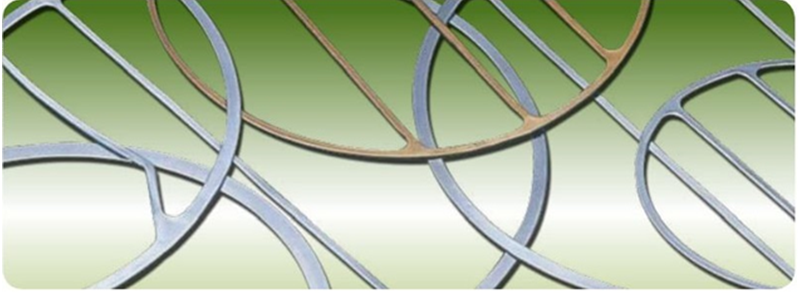

Double Jacket Gasket

KUKIL INNTOT metal jacketed gaskets are specially designed and widely used on smooth flange applications and are ideal for Heat Exchangers, Auto Claves, Columns, Flue Stacks, Boilers, Gas Mains, Valve Bonnets. Pumps and similar services.

They comprise a soft pliable filler core surrounded by a metal jacket which may totally or partially enclose the filler. This metal jacket provides the mechanical stregth to contain the filler and is selected from material which is suitable to resist chemical attack from the fluid to be sealed and also the operationg temperature. The combination of these two components produces a gasket which is resilient and successful in a wide range of services particularly in the petrocarbon lndustries.

KUKIL INNTOT metal jacketed gaskets are available in a comperhensive selection of materials and are custom built to clients specific design requirements and are almost without any size limitations. Each gasket is individually hand made with meticulous care, by our highly skilled craftsmen, to ensure of fitting and long service life.

Ring Joint Gasket

Ring joint gasket is a type of pressure energized gasket used on pipe flanges, perssure vessels, valve bonnets handling, high pressure steam, gas, hot oil, solvent vapor at high temperature.

KUKIL INNTOT's experienced technology offers many different types so that customers may select the most sutiable one in accordance with operating conditions.

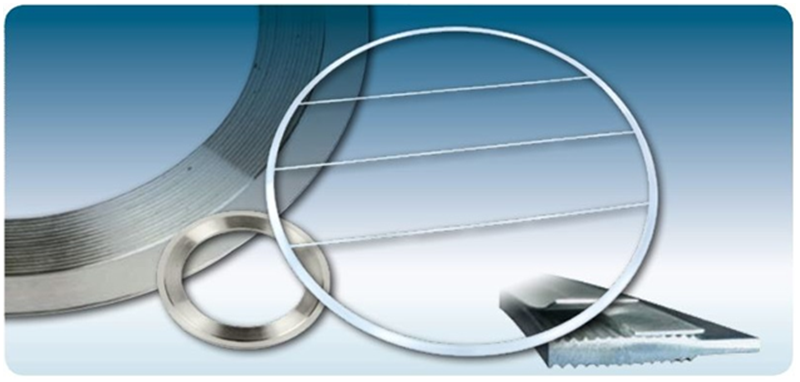

Serrated Metal Gasket

Serrated Metal Gasket is normally called Kammprofile Gasket and widely used on High perssure & high temperature plumbing flanges and is ideal for the pressure vessels, heat exchangers and Valve bonnet.

Flat Metal Gasket

Flat Metal Gasket is general purpose gasket that has been used for a long time.

Flat Metal Gasket is widely used for applications from low temperature and low pressure to high temperature and high pressure.

The thickness is generally 1.0mm, 1.5mm, or 3.0mm, and the gasket is made of cold rolled metal plate with a clean surface.

Enough compressive loads are required ot accomplish the seal between two mating metals.

- Low compressive loads : The mating surface of the flange is poorly compressed, resulting in leakage.

- Excessive compressive loads : The flange wraps and bolt expands, resuliting in leakage.

The material used must be softer than the flange (lower than 30 ~ 40 HB).

Use of layers of gasket paste or GRAFLEX improves sealing.

Major applications : Flanges of steam and process line, towers, vessels, heat exchangers, and valve, bonnet, etc.

Metal O-Ring Gasket

Metal Tube O-ring is only gasket made of metal tube which is formed and special welded into a round or other shapes. The gasket is provided with various advantages and it can be sealed with low tightening power, can be formed into various shape according to the shape of matrix face and can be used for high pressure, high temperature and ultra-vacuum services.

It is the most suitable gasket for seating such machinery and equipments that space factor and compactness are accounted much for designs. Special surface plating and coating is available according to need.

Lip-Seal Gasket

Weld Ring Gasket(Lip Seal Gasket) is applied to the expected leaking point (place) by using dangerous fluid and very difficult & extremely limited flange to open.

This gasket consisting of 2EA as one set is different from normal gaskets and applied to wide range of sizes from 3mm to 20mm as per each type. Also, Weld Ring Gasket has 100% leak-proof performance by weld seam.

Generally, it's material is equal to flange's and sometimes, a supporting gasket such as sprial Wound Gasket, Serrated Metal Gasket & Hiflex Metal Gaskets etc. is used for a leak test before welding by inserting it in the groove mechanized on the Weld Ring Gakset and by attaching sealing materials such as GRAFLEX, P.T.F.E etc. to the mechanized shape of serrated Metal Gasket on the one side of Weld Ring Gasket.

Using supporting gaskets is very useful for the test not only to prevent a leak on the corroded weld part but also to check & confirm a leak on the pressure vessel & pipe, etc before welding.

Table-1 shows basic types of Weld Ring Gasket and Table-2 shows Special types which is used for vibration absorbing when the flanges are under circumstances of the extension of the line by heat and high pressure & temperautre change.

Insulation Kit Gasket

KUKIL KINS-LA & LB is Insulation Gasket using semicircular rubber. Semicircular rubber is located in the groove on the gasket so that it functions for vacuum and for covering wide scope of pressure as well. It is used for the insulation of flange and for preventing corrosion which might be caused by the contact of different materials. Rubber material will be different according to kind of fluid.